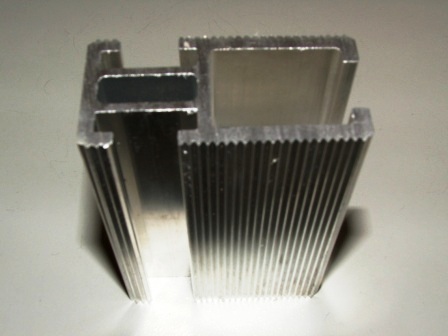

,strong>Aluminium extrusions are valued for strength, low weight, and cost efficiency. They’re used in transport, manufacturing, and automation where consistent, high-quality components are essential.

Applications of aluminium extrusion

- Solar energy systems

- Buses and rail transport

- Custom frames

- Marine equipment

- Safety railings

- Warehouse picking trolleys

- Automation systems

Fabrication Processes

Processes include cutting, milling, CNC machining, drilling, punching, welding, and assembly.

Finishing options to suit your application and environment:

- Mill finish

- Powder coating

- Anodising

Serving clients across Australia

Based in Sydney, NSW, we work with business clients nationwide, including regional and remote areas. Most fabrication is completed locally, Some clients ask for fabrication from Vietnam..

Examples of custom applications

Made‑to‑order solutions include warehouse and order picking trolleys, medical and food service carts, and specialised industrial equipment.

Contact us

Call AccuFab Solutions to discuss your aluminium extrusion requirements.

Fabrication and manufacturing of stainless steel, aluminium, and steel — Sydney, NSW, Australia