Custom stainless steel fabrication in Sydney — from warehouse trolleys and enclosures to benches, cabinets, display stands, and industrial components. We work with businesses across a wide range of industries.

AccuFab Solutions represents several select metal fabricators and manufacturers.

Stainless Steel Fabrication

304 and 316 grade fabrication for commercial kitchens, healthcare facilities, laboratories, warehouses, and industrial environments. These materials offer exceptional durability, corrosion resistance, and hygienic properties, making them suitable for both high‑use and sensitive applications. Learn more about stainless steel fabrication services.

Industries Served:

- Warehousing & logistics

- Commercial kitchens & food processing

- Healthcare & laboratories

- Industrial manufacturing

- Government and public sector

Processes Include:

- Laser cutting and CNC punching for precision components

- Welding, folding, drilling, and perforating

- Custom finishes: raw, brushed, and powder-coated

Featured Clients

Leading organisations include:

- NSW Health

- Sydney based Councils

- UNSW

- ACT Government

- StarTrack

- University of Sydney

- DHL

- Transport for NSW

- Ausgrid

- Australian Department of Defence

We focus on providing accurate delivery times, quality, service and competitive prices, by offering prompt, professional and reliable personalised service that you can count on.

Multinational, regional, remote, and local clients across Sydney, Newcastle, Wollongong, and across Australia and New Zealand rely on us for their diverse, high-quality metal fabrication requirements.

Examples of Stainless Steel Fabrication Projects

Warehouse & Order Picking Trolleys

View Warehouse & Order Picking Trolleys →

Custom Trolleys

Industrial Trolleys

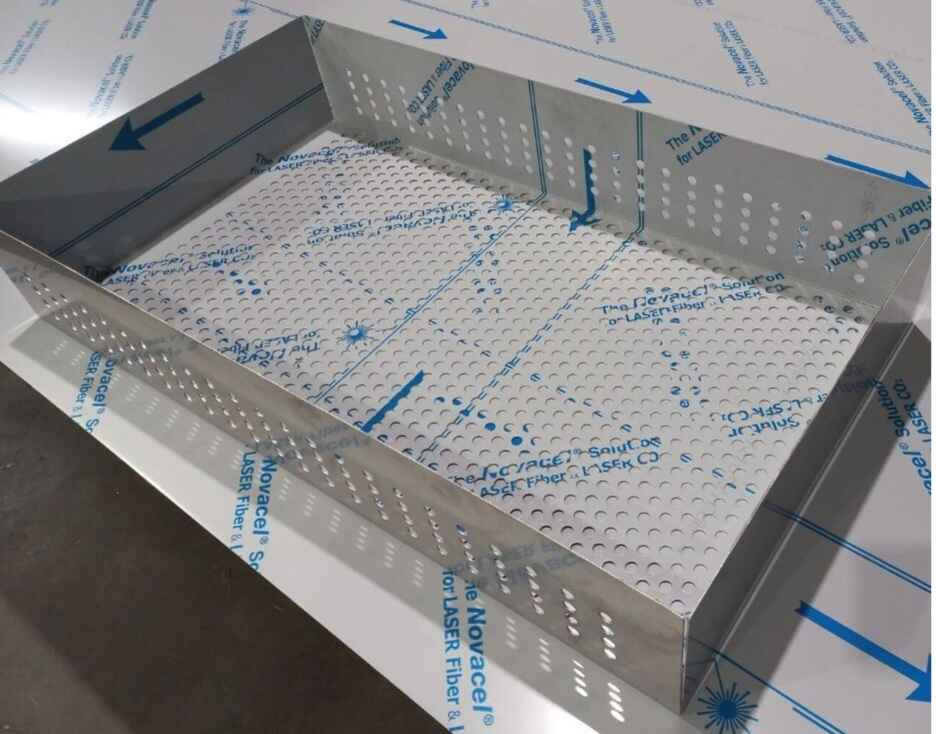

Stainless Steel Cabinets & Enclosures

Explore Sheet Metal Fabrication →

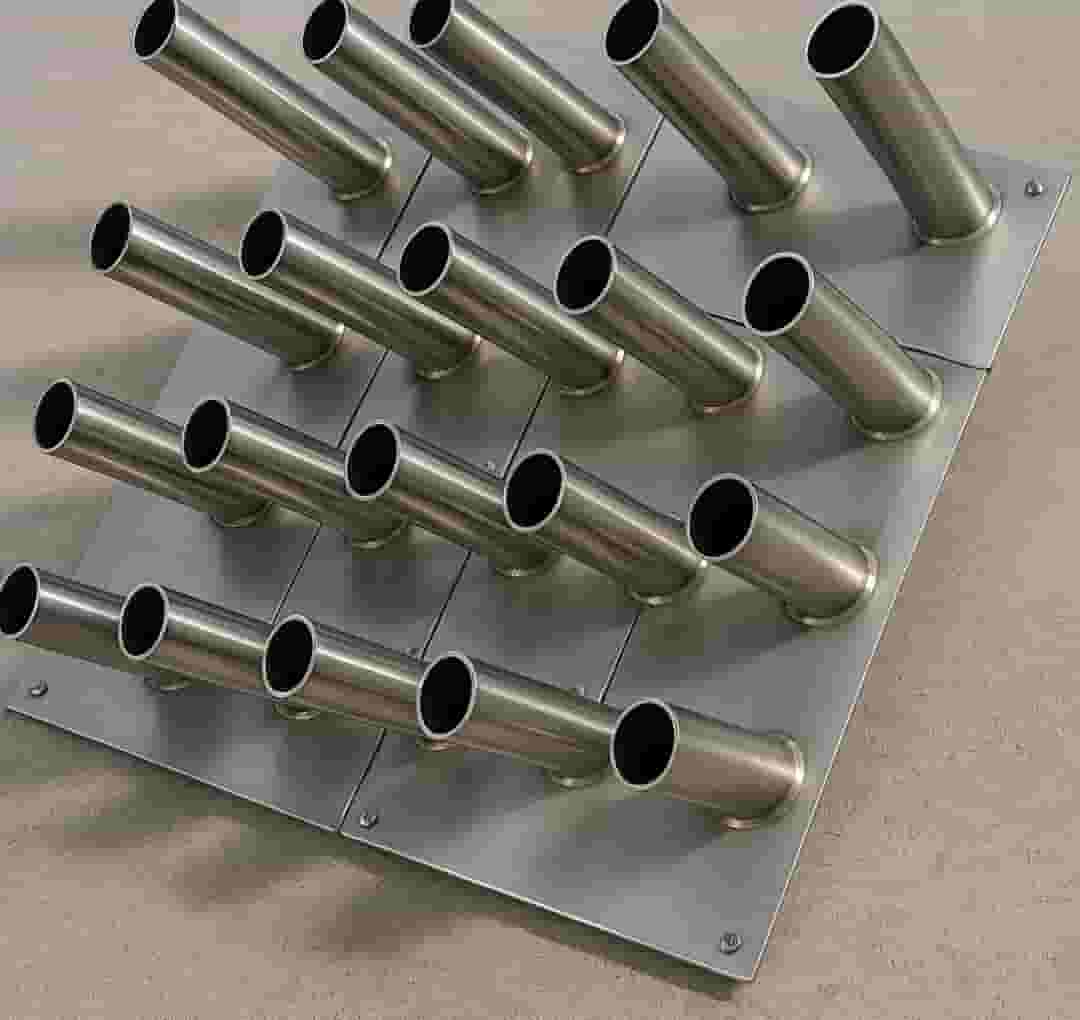

Stainless Steel Display Stands

Learn more about custom stands →

Frequently Asked Questions

What materials do you work with?

We work primarily with 304 and 316 grades due to their durability, corrosion resistance, and hygienic properties. We also fabricate using aluminium, mild steel, copper, and select plastics for specialised applications.

What finishes are available for stainless steel?

Raw, brushed, and powder-coated finishes to suit durability, hygiene, and aesthetic requirements.

How long does a typical project take?

Lead times vary depending on the product, size, and quantity. We provide accurate timelines during quoting.

What industries do you typically work with?

We work with clients in warehousing & logistics, commercial kitchens, healthcare & laboratories, industrial manufacturing, government, and educational institutions.

What custom products can be made from perforated or patterned stainless steel?

Perforated trays, plates, panels, enclosures, and custom components using laser cutting, CNC punching, and folding techniques.

How can I request a quote?

You can contact us directly via our contact page or request a quote for your custom stainless steel project, providing specifications, quantities, and any relevant drawings.